Kitting Services

At OFS, we can customize your kitting without the customized expense.

Let’s look at kitting in the context of a larger production process:

- Storage: The manufacturer stores its parts inventory at OFS.

- Kitting: When it’s time for parts to be used in production, OFS pulls them and compiles them into kits.

- Delivery: OFS delivers the kits to the manufacturer. This step is also referred to as “just in time (JIT)” delivery – the manufacturer only has the parts during the specific time frame that they are needed.

- Production: The manufacturer’s associates build the final products using the supplied kits.

- Packaging + Distribution: OFS can then custom package the final products and deliver them to their destination.

In this model, time and efficiency improvements realized through custom kitting services are maximized by OFS’s involvement in other key parts of the production process such as storage, packaging, and JIT delivery.

Advantages of Custom Kitting Services

There are several advantages of OFS custom kitting services, including the following.

- Save space. Instead of being a storage warehouse for boxes of parts and materials, your floor space could be used for production only, thereby increasing throughout. When you need these materials, OFS will deliver them just in time.

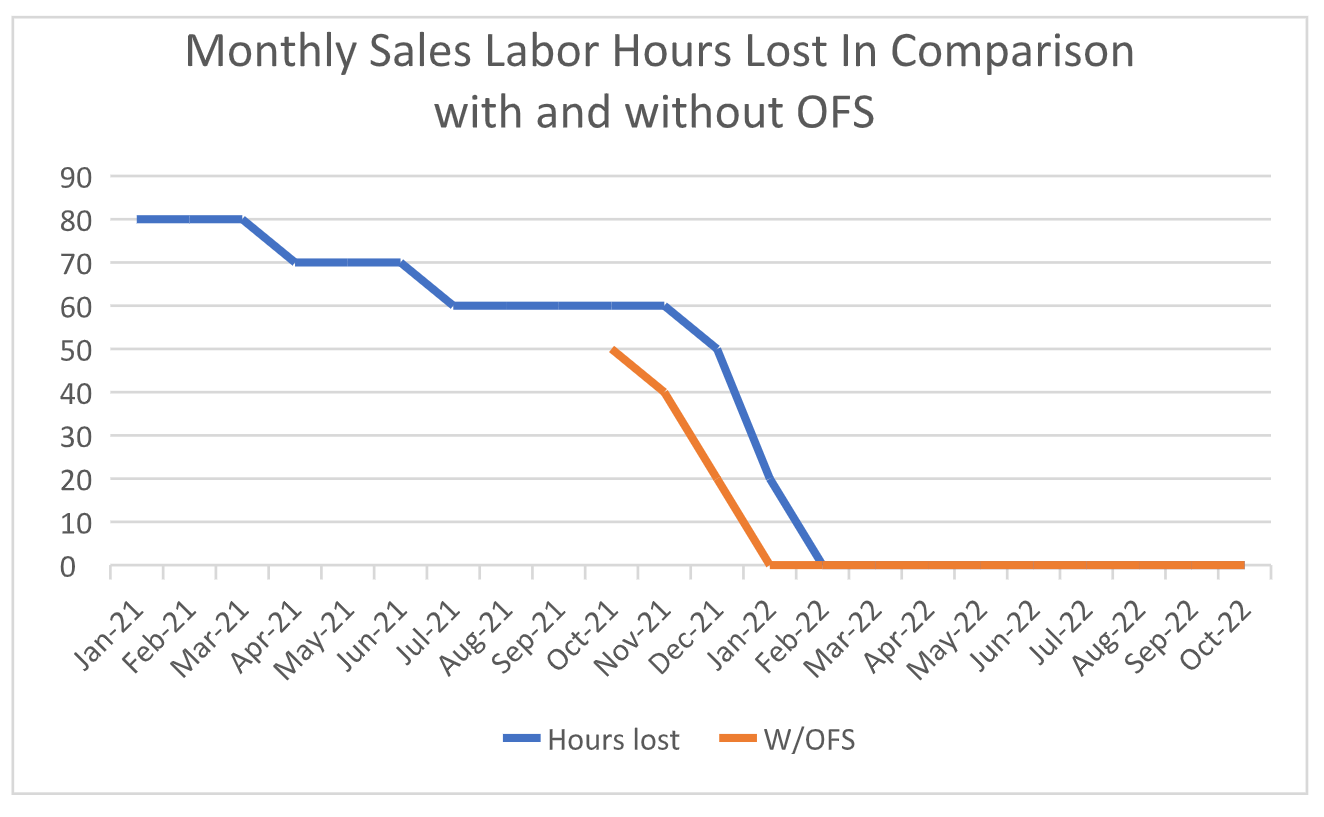

- Save time and money. As associates no longer need to spend time finding and compiling parts before getting on the actual production work, you optimize your labor costs and time management. This is no small perk at a time when warehouse associates are harder to find and more expensive than ever.

- Optimize your supply chain. With disruptions now common throughout the entire supply chain, you can mitigate impacts to your operations by ordering as much inventory as you need. While you may not have the space for it, OFS does.